Imagine you’re an astronaut, 250 miles above Earth on the International Space Station (ISS). A critical tool breaks—a specialized wrench or a custom valve fitting. On Earth, you’d order a replacement. In orbit, until recently, you’d wait months for the next resupply mission, hoping a workaround would suffice. But today, you simply walk over to a specialized machine, input a design file beamed from Earth, and a few hours later, you’re holding a brand-new, made-in-space part. This isn’t science fiction. This is the reality of 3D printing in microgravity, a technological leap quietly revolutionizing how we live and work in space.

The ability to manufacture objects layer-by-layer in the weightlessness of space is more than a neat trick. It’s a paradigm shift for space exploration, turning the concept of self-sufficiency from a dream into a tangible mission plan. From printing tools and satellite components to dreaming of entire lunar habitats, in-space additive manufacturing is the foundational technology that will allow humanity to become a truly spacefaring species. Let’s dive into the fascinating challenges, breakthroughs, and cosmic potential of building things where there is no “down.”

Why You Can’t Just Take a Regular 3D Printer to Space

To appreciate the marvel of microgravity 3D printing, you first have to understand why our trusted Earth-based printers would fail spectacularly off-world. Gravity, it turns out, is a silent partner in the additive manufacturing process.

On Earth, gravity provides constant orientation, heat management, and structural support during printing. The molten plastic or metal deposited by the printer’s extruder stays where it’s put, cooling and solidifying predictably. In microgravity, that fundamental force is virtually absent. This creates a host of unique challenges:

- The Blob Problem: Without gravity, surface tension reigns supreme. Molten material doesn’t want to stay in a neat bead; it wants to form a floating, shimmering blob. Getting it to adhere precisely to the build plate and subsequent layers requires entirely new approaches.

- Heat Doesn’t Rise: Convection—where hot air rises and cool air sinks—doesn’t happen in microgravity. Heat from the printed part just lingers, creating a potentially dangerous bubble of hot air and risking warping or improper curing of the material.

- Powder Peril: Many advanced 3D printers on Earth use fine metal or polymer powders. In a spacecraft, loose, floating powder is a nightmare—a hazard for sensitive equipment and astronauts’ lungs. Containing and managing these materials is a critical engineering hurdle.

- Structural Integrity: A part printed in microgravity might have different internal layer bonding and crystallinity than its Earth-made counterpart. Will it be as strong? As reliable? Understanding microgravity material science is key to trusting these printed parts with human lives.

Overcoming these issues wasn’t a matter of tweaking a settings file; it required reimagining the core mechanics of 3D printing for an environment where the rules of physics are written in a different dialect.

Breaking Ground (in Zero-G): The Pioneering Experiments

The journey to printing in space began with bold experiments that proved the concept was not only possible but practical.

The First Print: Made In Space and NASA’s Historic Partnership

The watershed moment came in 2014. A company named Made In Space, in collaboration with NASA, launched the 3D Printing in Zero-G Technology Demonstration to the ISS. This was the first dedicated 3D printer designed from the ground up for microgravity.

The printer used a fused filament fabrication (FFF) process, similar to common desktop printers, but with crucial modifications. It was designed to operate safely in a sealed environment, manage its heat and emissions, and, most importantly, overcome the blob issue through precise control of material extrusion, temperature, and adhesion.

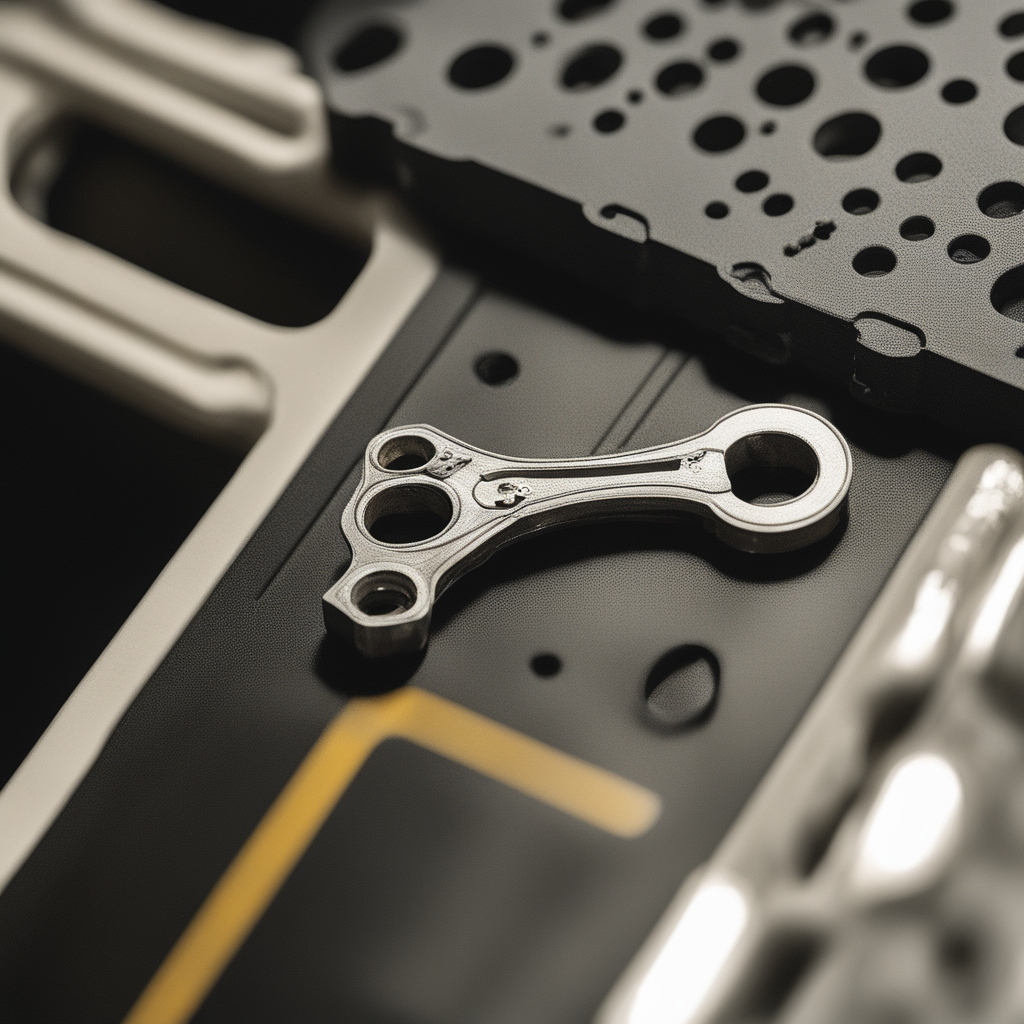

On November 25, 2014, it printed its first object: a simple faceplate of the printer itself. This was followed by a series of test coupons, wrenches, and tools. The success was monumental. It proved that:

- Microgravity fabrication was viable.

- The parts were comparable in strength to Earth-printed equivalents.

- The process was safe for the ISS and its crew.

Perhaps the most iconic print was a ratchet wrench. The design file was emailed from Earth to the station, and the wrench was printed on demand. For the first time in history, a tool was manufactured in space, on-site, without ever having existed on Earth. This was the ultimate validation of the “UPS in space” concept. You can read the official NASA summary of this landmark mission here.

Evolving the Tech: The Refabricator and Recycler

Building on this success, the focus shifted from simple demonstration to creating a sustainable, circular economy in space. Launching masses of printer filament is expensive. What if you could recycle plastic waste and old prints into new filament?

Enter the Refabricator. This NASA-developed payload, installed on the ISS, was the first integrated system capable of both recycling plastic waste into filament and 3D printing new items with it. Imagine an astronaut feeding a broken food container or a discarded tool into one end, and the machine producing fresh filament to print a new medical syringe or experiment part at the other. This closed-loop system is a critical step toward long-duration missions, where every gram of material must be utilized to its fullest potential. NASA provides a detailed look at this groundbreaking technology here.

The European Contribution: The Metal 3D Printer

While polymers are versatile, the future of in-space construction hinges on metal. In 2023, the European Space Agency (ESA), in collaboration with Airbus, installed the first metal 3D printer on the ISS’s Columbus module.

This printer uses a technique called laser powder bed fusion. Instead of extruding molten plastic, it uses a high-power laser to melt fine metal powder (stainless steel, in this case) in a controlled, sealed environment. Printing metal in microgravity is a far greater challenge due to the powder hazard and the intense heat involved, but the rewards are immense. Metal parts are stronger, more heat-resistant, and suitable for critical structural and mechanical applications.

The first prints from this machine are being returned to Earth for rigorous testing, comparing them to identical parts made on the ground. The data will be invaluable for understanding how microgravity affects the metallurgical properties of printed parts. ESA’s announcement of this project marks a major leap forward here.

The Tangible Benefits: Why This Changes Everything for Spaceflight

So, we can print in space. But why is this such a game-changer? The advantages permeate every aspect of space mission design and operation.

1. Unprecedented Logistics Resilience

This is the most immediate benefit. The ability to print spare parts on-demand eliminates the need to anticipate and launch every possible spare for a multi-year mission. It turns a rigid, finite inventory into a flexible, digital library. A broken hatch handle, a custom connector for an experiment, or a personalized medical device—all can be fabricated in hours, not months. This reduces risk, increases crew safety, and fundamentally changes the logistics model for deep-space travel.

2. Mass Savings and Cost Reduction

Launch mass is the single biggest cost driver in spaceflight. Every screw, bracket, and tool you launch costs thousands of dollars per kilogram. By sending digital files and raw material (which can often be multipurpose), you replace heavy, pre-manufactured spares with lightweight feedstocks. A single spool of advanced polymer can be the “raw material” for hundreds of different parts. The mass savings are exponential and make ambitious missions to the Moon and Mars economically more feasible.

3. Design Freedom and Performance Optimization

Parts designed for space often have to survive the brutal vibrations of launch. This leads to over-engineering—making them heavier and bulkier than they need to be for their in-space function. With in-space manufacturing, you can design parts that are optimized for microgravity performance, not launch survival. You can create intricate, lightweight, organic shapes (think bone-like lattices) that are impossible to make with traditional machining, resulting in stronger, lighter, and more efficient spacecraft systems.

4. The Path to In-Situ Resource Utilization (ISRU)

This is the holy grail. The ultimate goal is to stop bringing material from Earth altogether. In-Situ Resource Utilization (ISRU) means using the materials you find at your destination. On the Moon, that could be lunar regolith (moon dust). On Mars, it could be the iron-rich soil or atmospheric CO2.

Experiments are already underway to 3D print with simulated lunar and Martian regolith. Imagine autonomous robots sintering moon dust with concentrated sunlight or lasers to create landing pads, radiation shields, and eventually, entire habitat structures. NASA’s 3D-Printed Habitat Challenge spurred incredible innovation in this area, with teams designing structures that could be built autonomously from local materials. By printing with what’s already there, we slash mission costs and establish a permanent, sustainable presence.

The Future is Being Printed, Layer by Layer

The roadmap for 3D printing in microgravity points toward ever larger scales and more ambitious applications.

- Large-Scale Spacecraft Structures: Future telescopes, communication antennas, and even spacecraft frames could be printed in orbit, far exceeding the size limits of any rocket fairing. This would enable next-generation astronomy and deep-space exploration vehicles of unimaginable scale.

- Bioprinting in Space: The unique environment of microgravity is also ideal for bioprinting tissues and organs. Without gravity-driven sedimentation, cells can be arranged in three dimensions with greater precision. Research on the ISS is already exploring printing cardiac tissue and cartilage. In the long term, this could mean printing personalized medical patches or even complex tissues for astronauts on long-duration missions.

- The Orbital Factory: We may see dedicated manufacturing platforms in Low Earth Orbit (LEO), producing high-value products that benefit from microgravity, such as flawless fiber optic cables or unique pharmaceutical crystals, and then shipping them back to Earth.

Conclusion: From Supplying to Surviving to Thriving

3D printing in microgravity represents more than a new tool; it represents a new philosophy for space exploration. We are transitioning from a model of carrying everything we might need to one of taking the means of production with us.

It shifts the paradigm from mere supply to empowered survival, and ultimately, to sustained growth. It’s the technology that will let astronauts fix their home, build their tools, and eventually, construct their outposts from the very soil beneath their boots.

The quiet hum of a 3D printer on the ISS is the sound of a new age. It’s the sound of resilience, of adaptability, and of a future where humanity is no longer an anxious visitor in the cosmos, but a capable and creative resident. The next chapter of our space story won’t just be written—it will be designed on a computer a quarter-million miles away and printed, layer by layer, in the silent factory of space.

FAQ Section

Q: Why can’t we use a normal 3D printer in space?

A: Earth-bound printers rely heavily on gravity. In microgravity, molten plastic would form floating blobs instead of neat layers, heat doesn’t rise to dissipate, and loose powder materials would become a hazardous, floating mess. Printers for space require complete re-engineering to manage material behavior, adhesion, and heat in a weightless environment.

Q: What was the first thing ever 3D printed in space?

A: The first object was a simple faceplate for the printer itself, printed by Made In Space’s 3D printer on the International Space Station in November 2014. Soon after, they famously printed a functional ratchet wrench, demonstrating the ability to create tools on-demand from digital files sent from Earth.

Q: What materials can be 3D printed in microgravity?

A: Currently, specialized polymers and plastics are the most common, often recycled in a closed-loop system like the Refabricator. A major breakthrough occurred with the installation of the first metal 3D printer (using stainless steel) on the ISS in 2023. Research is also ongoing into printing with simulated lunar and Martian regolith (soil).

Q: How strong are 3D-printed parts made in space compared to Earth-made ones?

A: Extensive testing by NASA and other agencies has shown that parts printed in microgravity have comparable tensile strength and performance to their Earth-printed counterparts. However, understanding the long-term effects of microgravity on material structure, especially for metals, is an active area of research.

Q: What’s the biggest benefit of in-space manufacturing?

A: It fundamentally changes space mission logistics. The ability to print spare parts, tools, and components on-demand creates unprecedented resilience, reduces the need to launch every possible spare (saving massive cost and mass), and enables the design of parts optimized for zero-g, not launch survival.

Q: Could we really 3D print a moon base?

A: Yes, this is a serious and active research path known as In-Situ Resource Utilization (ISRU). The concept involves using autonomous robots or systems to 3D print habitats, landing pads, and radiation shields using lunar regolith as the primary building material. This would eliminate the need to transport all building materials from Earth, making a sustainable lunar presence feasible.

Q: Is bioprinting (tissues/organs) possible in microgravity?

A: Surprisingly, microgravity may be ideal for certain types of bioprinting. Without gravity pulling down cells, they can be assembled in three dimensions with greater precision. Experiments on the ISS are already exploring printing cardiac tissue and cartilage, with the long-term goal of advancing medical science both for astronauts and Earth-based medicine.

Q: Where can I learn more about official NASA and ESA projects in this field?

A: You can explore NASA’s dedicated pages for the 3D Printing in Zero-G mission and the Refabricator recycler. The European Space Agency also details its pioneering metal 3D printer experiment on the ISS.