Look up tonight. That steady, bright dot arcing across the twilight sky isn’t a star or a plane. It’s the International Space Station (ISS), a bustling scientific outpost orbiting 250 miles above Earth. Inside its labyrinth of modules, amid the floating astronauts and whirring life support systems, a quiet industrial revolution is taking place. We’re not just doing science up there anymore; we’re learning to build. This is the frontier of in-space manufacturing, a field poised to transform everything from deep-space exploration to the products we use on Earth.

For decades, every single item on the ISS—every bolt, every tool, every spare part—had to be painstakingly designed, built, tested on Earth, and launched on a rocket at a cost of roughly $10,000 per pound. Imagine a car repair where you had to predict every potential part failure years in advance and ship a whole hardware store into orbit, just in case. It’s inefficient, limiting, and downright unsustainable for longer missions to the Moon or Mars.

But what if astronauts could become cosmic makers? What if they could fabricate what they need, when they need it, from raw materials or even recycled waste? This isn’t science fiction. It’s the critical mission of metal and polymer fabrication experiments on the ISS. Let’s dive into this zero-gravity workshop and explore how it’s shaping our future.

Why You Can’t Just Take a Factory to Space: The Microgravity Challenge

Before we marvel at the successes, we must understand the bizarre environment of microgravity. It’s not just about things floating. It fundamentally alters the physics we take for granted.

- Heat Behaves Differently: On Earth, hot air rises because it’s less dense than cold air—a process called convection. In microgravity, there’s no “up,” so hot air doesn’t rise. It just sits there, creating a bubble of intense heat. This makes processes like welding or melting metals incredibly tricky, as heat doesn’t dissipate predictably. Managing this “thermal runaway” is a huge hurdle.

- Surface Tension is King: Without gravity to pull liquids into familiar shapes, surface tension dominates. Molten metal or polymer wants to form a perfect sphere, the shape with the smallest surface area. Trying to extrude it into a long, straight rod or a flat sheet requires entirely new techniques to control this liquid ball.

- Dust and Debris: On Earth, sawdust or metal filings fall to the floor. In space, they float, posing a risk to sensitive equipment, optics, and astronauts’ lungs. Any fabrication system must be hermetically sealed or equipped with sophisticated containment and filtration.

Overcoming these challenges isn’t just an engineering problem; it’s a rewriting of the fundamental rulebook for manufacturing.

The Polymer Pioneers: 3D Printing in the Void

The first major victory for in-space fabrication came with polymers, thanks to additive manufacturing (3D printing). The goal was simple yet profound: print a tool, on-demand, in orbit.

In 2014, NASA, in partnership with the company Made In Space, launched the 3D Printer to the ISS. It was a historic moment. The first object printed was a simple faceplate for the printer itself—a humble part, but it proved the concept. Since then, the technology has evolved dramatically.

- The Refabricator: This groundbreaking device, also developed with Made In Space, is a closed-loop recycler. It can take old plastic prints or packaging, melt them down, and reuse the material to print new items. It’s the ultimate in sustainable, circular manufacturing for space.

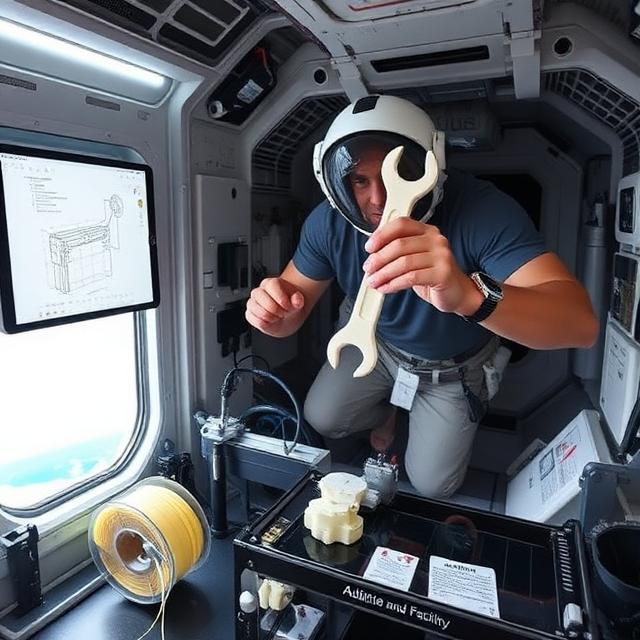

- The Additive Manufacturing Facility (AMF): This is the ISS’s permanent, commercial “machine shop.” It has printed hundreds of parts, from custom wrenches and crew medical guides to complex scientific instruments. Researchers on Earth can design a part, upload the file, and have it printed by the crew within days.

Why This Matters on Earth: The lessons learned from printing in microgravity are directly improving terrestrial 3D printing. Better control of material flow, thermal management, and printer reliability for remote locations (like offshore oil rigs or remote military bases) are all benefits flowing from this orbital R&D. NASA has a full repository of these experiments you can explore: NASA’s In-Space Manufacturing Project.

The Next Frontier: Melting Metal in Microgravity

While plastic printing is now routine, working with metals is the true holy grail. Metals are stronger, more durable, and capable of handling the extreme temperatures and stresses of space. But melting metal in microgravity? That’s a whole different ball game.

Several landmark experiments are paving the way:

- The “Saffire” of Manufacturing: SPEE3D’s Experiment

In 2023, an Australian company, SPEE3D, sent its space-enabled metal 3D printer to the ISS. Their technology is unique. Instead of using a laser to melt powder (which creates dangerous, floating particles), they use a process called “cold spray.” It essentially blasts metal powder particles at a surface at supersonic speeds. The particles deform and bond to each other on impact, building up a solid metal part layer by layer—all without ever creating a molten pool. It’s faster, safer, and brilliantly adapted to the space environment. - The European Approach: Metal 3D Printing with Lasers

The European Space Agency (ESA) has taken on the molten metal challenge directly. Their Metal 3D Printer, developed with Airbus, uses a stainless-steel wire fed into a laser melt pool. The entire process occurs inside a sealed, inert gas box to contain fumes and spatter. Successfully demonstrating this in 2023 proved that high-quality, dense metal parts can be created in orbit. You can read about ESA’s ambitious plans for in-orbit manufacturing here: ESA – Fabricating the Future in Space. - The Welding Experiments: The First Sparks

Going back further, experiments like SOLEXBRA and others have tested electron beam welding in a vacuum chamber on the ISS. These studies gave us crucial data on how molten metal behaves when it’s not being pulled down by gravity, informing the designs of today’s more advanced systems.

The Dream: In-Space Construction and the “Archinaut”

Fabricating small parts inside the station is one thing. But what about building outside? Imagine assembling giant radio antennas, vast solar arrays, or even new spacecraft hulls in the vacuum of space itself.

This is the goal of projects like NASA’s OSAM-2 (On-Orbit Servicing, Assembly, and Manufacturing 2) mission and the work of companies like Made In Space with their Archinaut concept. The idea is to use robotic arms equipped with additive manufacturing tools and assembly capabilities to construct large structures directly in orbit. These structures wouldn’t be constrained by the size of a rocket fairing; they could be football-field-sized, designed for optimal function in space, not for surviving launch.

The Humanized Impact: Why This Matters for the Rest of Us

This might all sound like niche space-tech, but the ripple effects are already reaching Earth.

- Medicine: The techniques for handling biological samples or growing tissues in microgravity are informing advanced bioprinting research on Earth, with potential for creating artificial organs.

- Advanced Alloys: The unique solidification processes in microgravity can create metal alloys with unprecedented internal structures—stronger, lighter, or with novel properties. This could revolutionize aerospace, automotive, and medical implant industries.

- Remote Industry: The robust, automated, and remote-operated fabrication systems developed for the ISS are blueprints for automated mining or construction in hazardous environments on Earth, from the deep sea to active volcanoes.

- A Sustainable Mindset: The closed-loop “recycle and re-print” mentality is a powerful model for combating waste and building a more circular economy on our home planet.

A Day in the Life: The Astronaut Fabricator

Let’s humanize this with a hypothetical scenario. It’s 2030, and astronaut Dr. Lena Chen is on a six-month tour aboard the Lunar Gateway, a station orbiting the Moon.

A critical sensor mounted on an external telescope breaks after a micrometeoroid strike. In the Apollo era, this might have ended the experiment. In the Shuttle era, they’d wait months for a resupply. But for Lena?

- She consults with ground-based engineers who design a reinforced replacement part in a few hours.

- The design file is beamed to the Gateway.

- Lena loads a cartridge of titanium alloy powder, recycled from previous mission packaging, into the station’s metal fabrication module.

- A robotic arm inside the sealed module uses an electron beam to precisely fuse the powder, layer by layer.

- Twelve hours later, she retrieves the finished, gleaming part.

- On the next spacewalk, she installs it. The telescope is back online.

This is the promise: resilience, independence, and limitless potential.

Conclusion: Building the Off-World Future

The work being done on metal and polymer fabrication aboard the ISS is more than a series of cool experiments. It is the foundational research for a future where humanity is no longer Earth-bound. It’s about turning space from a destination we visit into a place where we can live and work.

The tiny, spherical polymer bead formed in microgravity and the first perfectly formed metal bracket printed in orbit are more than just test samples. They are the first stitches in the fabric of a solar-system-wide civilization. They represent a shift from taking everything with us to learning to use the resources we find—and eventually, those we find beyond Earth.

So, the next time you see the ISS glide peacefully overhead, remember: it’s not just a laboratory. It’s a prototype factory, a testbed for the industrial age of space, and a beacon pointing toward a future where we build our dreams among the stars.

Further Reading & Sources:

- NASA’s In-Space Manufacturing Portal: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7959

- European Space Agency – Fabricating the Future: https://www.esa.int/Enabling_Support/Space_Engineering_Technology/Shaping_the_Future/Fabricating_the_future_in_space

- Made In Space (now part of Redwire Space): https://redwirespace.com/

- SPEE3D’s Space Experiment: https://www.spee3d.com/news/spee3d-completes-first-metal-3d-printing-experiment-in-space

FAQ: Space Manufacturing on the ISS

Q: What exactly is “in-space fabrication” or “in-space manufacturing”?

A: It’s the process of building, assembling, or creating physical objects in the space environment, rather than on Earth. On the ISS, this primarily involves technologies like 3D printing (for polymers and metals) and specialized welding. The goal is to move from carrying every single spare part to becoming self-sufficient, making what we need from raw materials or recycled waste in orbit.

Q: Why is it so hard to manufacture things in space? Isn’t it just a vacuum?

A: The biggest challenge isn’t the vacuum—it’s microgravity. Without gravity, basic physics we rely on changes. Heat doesn’t rise, so managing temperatures for melting materials is tricky. Liquids (including molten plastic or metal) form into floating spheres due to surface tension. Plus, any dust, filings, or fumes don’t settle; they float, creating hazards. Every process has to be completely reimagined for these conditions.

Q: What kinds of things have actually been 3D-printed on the ISS?

A: Hundreds of items! The range is impressive: from practical tools like custom wrenches, socket heads, and antenna mounts to parts for the station itself, like air duct connectors. They’ve also printed complex scientific equipment components and even ceremonial objects, like a “space wrench” file that was emailed to the station and printed within hours. The first item was a simple faceplate for the printer, proving the concept.

Q: I’ve heard of plastic printing, but how do you possibly 3D print with metal in space?

A: This is the cutting edge! Two main methods are being tested:

- Cold Spray (SPEE3D): This method doesn’t melt the metal. Instead, it blasts metal powder at supersonic speeds at a surface, where the particles deform and bond on impact—like a high-tech, solid-state welding process. It’s fast and avoids the dangers of molten metal.

- Laser Melting (ESA/NASA): This uses a focused laser to create a tiny melt pool on a bed of metal powder or into which a metal wire is fed. It carefully builds the part layer by layer inside a sealed, inert gas chamber to contain any particles or fumes.

Q: What are the biggest benefits of learning to manufacture in space?

A: The benefits are transformative:

- Mission Resilience: Astronauts can fix broken parts on-demand, turning a potential crisis into a simple repair job.

- Mass & Cost Savings: Reduces the need to launch every possible spare part, saving billions in launch costs and freeing up spacecraft volume.

- Deep-Space Exploration: For missions to Mars, waiting for a resupply from Earth isn’t an option. Crews must be able to make and repair their own equipment.

- Superior Structures: The ability to build large structures (like telescopes or solar arrays) directly in space means they can be bigger, lighter, and more precise than anything built to survive a rocket launch.

Q: Does this research have any uses back on Earth?

A: Absolutely. The innovations driven by space constraints lead to breakthroughs at home. The need for robust, remote-operated, and highly efficient printers is perfect for:

- Creating parts in remote locations (e.g., on ships, oil rigs, or military bases).

- Developing new metal alloys with unique properties.

- Advancing bioprinting techniques, inspired by handling materials in microgravity.

- Promoting a closed-loop, zero-waste manufacturing mindset that is crucial for sustainability.

Q: What’s the ultimate goal? Will we see factories in space?

A: The long-term vision is indeed large-scale, automated orbital manufacturing. Imagine robotic systems using materials from asteroids or the Moon to build vast satellites, space-based solar power stations, or even spacecraft for interplanetary travel. Projects like NASA’s OSAM-2 and concepts like Archinaut are the first steps toward this future, where we construct in space, for space, freeing ourselves from the constraints of Earth’s gravity well.

Q: Where can I learn more about specific experiments?

A: Great question! You can follow the latest developments directly from the source:

- NASA’s In-Space Manufacturing Project: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7959

- European Space Agency’s Fabrication Projects: https://www.esa.int/Enabling_Support/Space_Engineering_Technology/Shaping_the_Future/Fabricating_the_future_in_space

Q: How can I see when the ISS is flying over my house?

A: You can spot it with your own eyes! It looks like a very bright, fast-moving star. NASA has a fantastic service called “Spot the Station” where you can sign up for alerts for your location: https://spotthestation.nasa.gov/. Next time you see it, you’ll know there’s a high-tech machine shop humming along inside.